Enhancing Safety in Automation: The Role of Frameless Bending Robot Safety Fences

Release Time:

Jul 08,2025

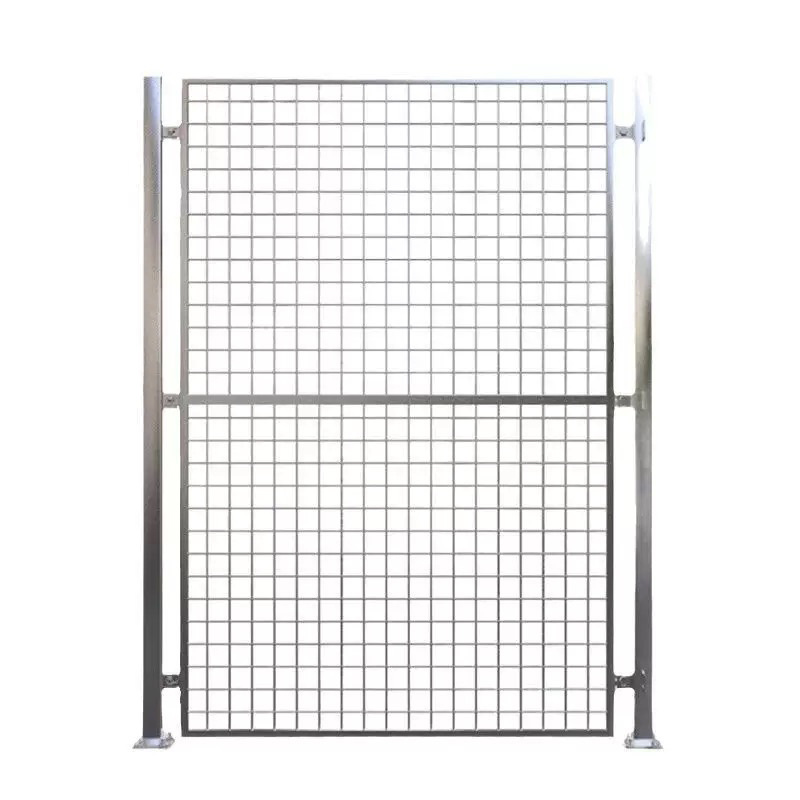

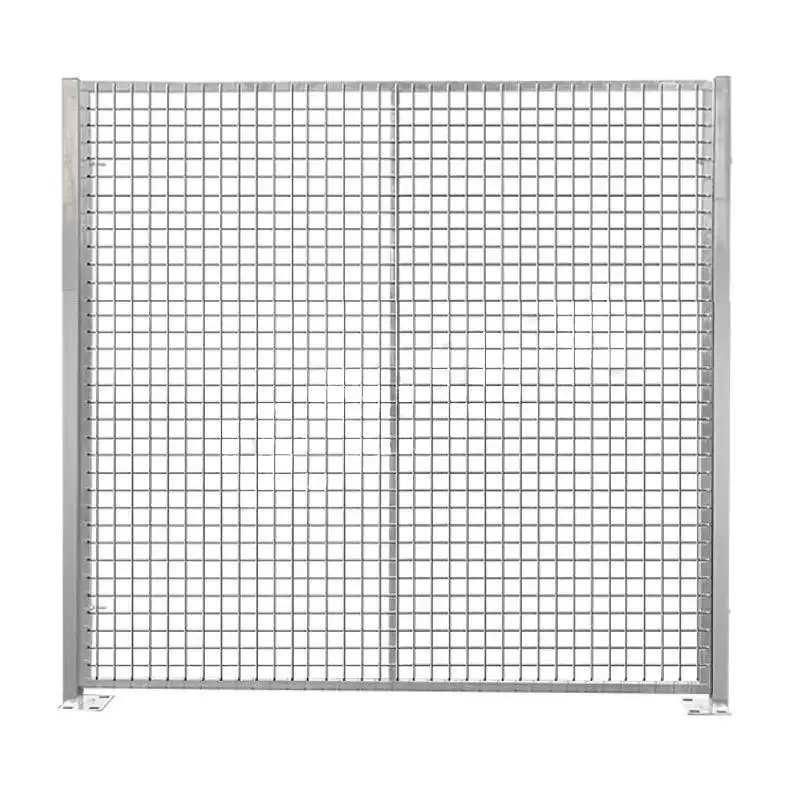

In the realm of automation, particularly within industries such as consumer electronics and commercial finance, ensuring the safety of both workers and machinery is paramount. One innovative solution that has emerged to address safety concerns is the frameless bending robot safety fence. This technology serves as a critical barrier, creating a safe work environment while facilitating the efficient

In the realm of automation, particularly within industries such as consumer electronics and commercial finance, ensuring the safety of both workers and machinery is paramount. One innovative solution that has emerged to address safety concerns is the frameless bending robot safety fence. This technology serves as a critical barrier, creating a safe work environment while facilitating the efficient operation of automated systems.

Frameless bending robot safety fences are designed to provide unobstructed visibility and access while maintaining necessary safety standards. Unlike traditional safety barriers, which can be bulky and limit visibility, frameless designs utilize transparent materials that allow operators to monitor processes in real time. This transparency can significantly reduce the risk of accidents, as operators are more aware of their surroundings.

These safety fences are particularly important in settings where bending robots operate. As these robots perform intricate tasks—such as bending, cutting, and assembling components—they may pose risks if not properly contained. The frameless design ensures that while the robots can function effectively, the area remains protected from unauthorized access. This dual functionality of promoting safety while enabling operational efficiency is a significant advantage.

Moreover, frameless bending robot safety fences are often engineered with flexibility in mind. They can be customized to fit various workspace layouts and can adapt to changes in production lines or workflow requirements. This adaptability is essential in industries that frequently experience shifts in demand or technological advancements. By utilizing a safety fence that can evolve with the workspace, companies can maintain high safety standards without compromising productivity.

In addition to promoting physical safety, the implementation of frameless bending robot safety fences can enhance compliance with industry regulations. Many workplaces are subject to strict safety standards; thus, investing in advanced safety solutions not only protects workers but also helps businesses avoid potential legal challenges. Organizations that prioritize safety are likely to foster a more positive work environment, leading to increased employee satisfaction and retention.

It's also worth noting that the integration of these safety fences can contribute to the overall efficiency of operations. By reducing the likelihood of accidents and downtime, businesses can streamline their processes. Furthermore, when employees feel safe, they are more likely to focus on their tasks, ultimately leading to improved performance and output.

In conclusion, frameless bending robot safety fences represent a vital advancement in the safety protocols within the consumer electronics and financial sectors. Their ability to enhance visibility, adaptability, and compliance makes them an essential investment for any organization relying on automated systems. By prioritizing safety through such innovative solutions, companies can ensure a secure and efficient working environment conducive to sustained success.

Frameless bending robot safety fences are designed to provide unobstructed visibility and access while maintaining necessary safety standards. Unlike traditional safety barriers, which can be bulky and limit visibility, frameless designs utilize transparent materials that allow operators to monitor processes in real time. This transparency can significantly reduce the risk of accidents, as operators are more aware of their surroundings.

These safety fences are particularly important in settings where bending robots operate. As these robots perform intricate tasks—such as bending, cutting, and assembling components—they may pose risks if not properly contained. The frameless design ensures that while the robots can function effectively, the area remains protected from unauthorized access. This dual functionality of promoting safety while enabling operational efficiency is a significant advantage.

Moreover, frameless bending robot safety fences are often engineered with flexibility in mind. They can be customized to fit various workspace layouts and can adapt to changes in production lines or workflow requirements. This adaptability is essential in industries that frequently experience shifts in demand or technological advancements. By utilizing a safety fence that can evolve with the workspace, companies can maintain high safety standards without compromising productivity.

In addition to promoting physical safety, the implementation of frameless bending robot safety fences can enhance compliance with industry regulations. Many workplaces are subject to strict safety standards; thus, investing in advanced safety solutions not only protects workers but also helps businesses avoid potential legal challenges. Organizations that prioritize safety are likely to foster a more positive work environment, leading to increased employee satisfaction and retention.

It's also worth noting that the integration of these safety fences can contribute to the overall efficiency of operations. By reducing the likelihood of accidents and downtime, businesses can streamline their processes. Furthermore, when employees feel safe, they are more likely to focus on their tasks, ultimately leading to improved performance and output.

In conclusion, frameless bending robot safety fences represent a vital advancement in the safety protocols within the consumer electronics and financial sectors. Their ability to enhance visibility, adaptability, and compliance makes them an essential investment for any organization relying on automated systems. By prioritizing safety through such innovative solutions, companies can ensure a secure and efficient working environment conducive to sustained success.

Hot Products