Understanding the Importance of Machine Guarding Fence Panels in Industrial Settings

Release Time:

Jul 13,2025

Understanding the Importance of Machine Guarding Fence Panels in Industrial Settings Table of Contents 1. Introduction to Machine Guarding Fence Panels 2. Why Machine Guarding is Crucial in Industrial Settings - 2.1 Safety Benefits of Machine Guarding Fence Panels - 2.2 Regulatory Compliance and Standards 3. Types of Machine Guarding Fence Panels - 3.1 Fixed Machine Guarding

Understanding the Importance of Machine Guarding Fence Panels in Industrial Settings

Table of Contents

1. Introduction to Machine Guarding Fence Panels

2. Why Machine Guarding is Crucial in Industrial Settings

- 2.1 Safety Benefits of Machine Guarding Fence Panels

- 2.2 Regulatory Compliance and Standards

3. Types of Machine Guarding Fence Panels

- 3.1 Fixed Machine Guarding

- 3.2 Removable Machine Guarding

4. Design Considerations for Fence Panels

- 4.1 Materials Used in Manufacturing Fence Panels

- 4.2 Ergonomics and Accessibility

5. Best Practices for Installation and Maintenance

- 5.1 Installation Process

- 5.2 Maintenance Tips for Longevity

6. Cost Implications of Machine Guarding Fence Panels

7. Real-World Case Studies on Machine Guarding Effectiveness

8. Conclusion: The Future of Machine Guarding in Industrial Settings

9. Frequently Asked Questions

Introduction to Machine Guarding Fence Panels

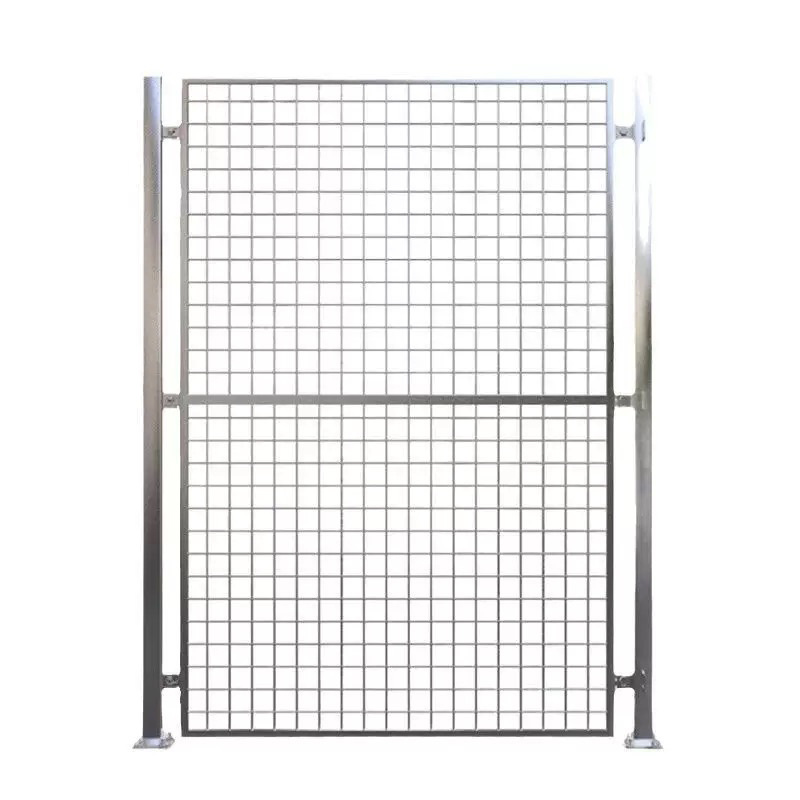

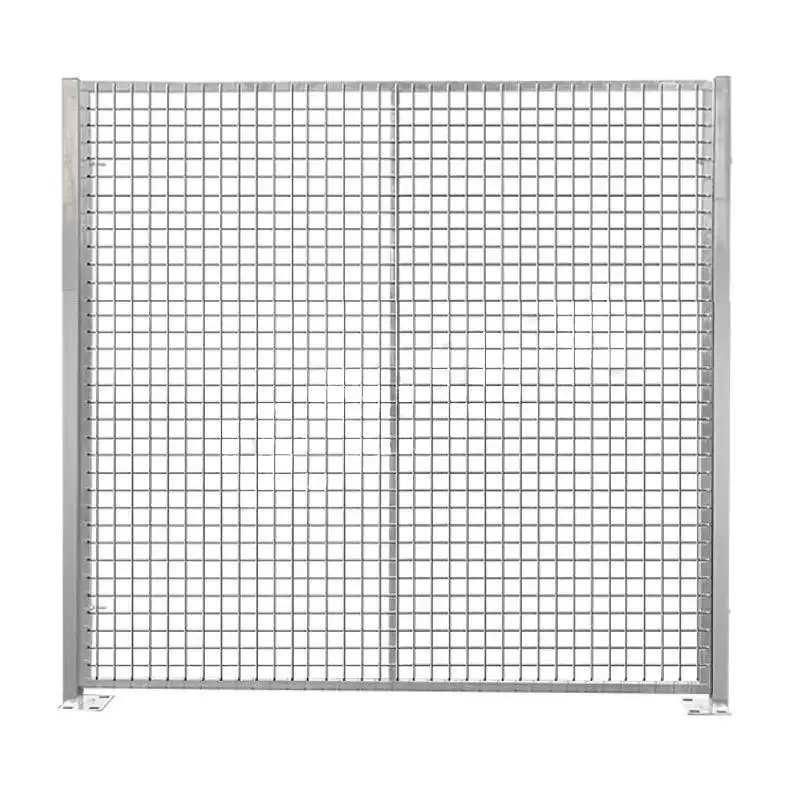

In today's industrial landscape, safety is paramount. As machinery becomes more advanced, the risks associated with its operation also increase. **Machine guarding fence panels** play a vital role in protecting workers from hazardous machinery and ensuring compliance with safety regulations. These panels serve as physical barriers that prevent unauthorized access to dangerous areas, effectively minimizing the risk of accidents and injuries.

Why Machine Guarding is Crucial in Industrial Settings

The significance of machine guarding in industrial settings cannot be overstated. Let's delve deeper into its importance.

Safety Benefits of Machine Guarding Fence Panels

First and foremost, the primary objective of machine guarding fence panels is to enhance safety. By creating a secure perimeter around hazardous equipment, these panels act as a deterrent to unauthorized personnel. They ensure that only trained and authorized employees can access areas where dangerous machines operate. This is crucial not only for preventing accidents but also for cultivating a culture of safety within the workplace.

Research has shown that industries that implement effective machine guarding measures significantly reduce the incidence of workplace injuries. By leveraging **machine guarding solutions**, companies can save on medical costs, workers' compensation claims, and potential litigation fees.

Regulatory Compliance and Standards

Another critical aspect of machine guarding is compliance with legal regulations. Organizations must adhere to specific safety standards set by governing bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States or similar entities worldwide. Non-compliance can result in severe penalties, including fines and legal repercussions.

Machine guarding fence panels are often designed to meet these regulatory standards. By investing in high-quality guarding solutions, companies not only protect their employees but also ensure they meet legal expectations, thereby safeguarding their reputation and operational integrity.

Types of Machine Guarding Fence Panels

Machine guarding solutions come in various forms, each designed to cater to specific safety needs and operational requirements.

Fixed Machine Guarding

Fixed machine guarding consists of permanent barriers that enclose hazardous machinery. These guards are typically made from robust materials and are securely mounted to provide an unmovable barrier. Fixed guards are ideal for machines that require constant protection when in operation. Industries such as manufacturing, textiles, and construction often rely on fixed machine guarding solutions to mitigate risks effectively.

Removable Machine Guarding

On the other hand, removable machine guarding offers flexibility. These panels can be easily taken down or adjusted to provide access for maintenance or operational needs. Removable guards are excellent for situations where machine operation varies frequently and require periodic access without compromising safety. However, it is essential that these guards are designed to be securely fastened when in place to maintain their protective function.

Design Considerations for Fence Panels

When selecting machine guarding fence panels, several design considerations must be taken into account to ensure their effectiveness.

Materials Used in Manufacturing Fence Panels

The materials used to manufacture machine guarding fence panels are critical to their overall performance. Panels are typically constructed from materials like steel, aluminum, or heavy-duty plastics. Each material offers specific advantages; for instance, steel provides durability and strength, while aluminum is lightweight and resistant to corrosion. The choice of material should align with the specific operational environment and intended use of the guarding solution.

Ergonomics and Accessibility

In addition to material selection, the ergonomics of machine guarding fence panels should also be considered. Panels should be designed to facilitate easy access for authorized personnel, without compromising safety. This includes considerations for height, visibility, and ease of use. Ergonomic design not only enhances safety but also contributes to employee productivity by allowing for seamless operation and maintenance.

Best Practices for Installation and Maintenance

To maximize the effectiveness of machine guarding fence panels, proper installation and maintenance are imperative.

Installation Process

The installation process should begin with a thorough assessment of the industrial environment. This includes evaluating the type of machinery in operation, identifying potential hazards, and determining the best locations for guarding panels. It's recommended to collaborate with safety experts during this phase to ensure compliance with all regulatory requirements.

Once the assessment is complete, panels should be installed according to the manufacturer’s specifications. Ensuring that guards are securely mounted and free from defects is crucial. Regular inspections should be conducted post-installation to verify that the guards remain intact and functional.

Maintenance Tips for Longevity

Regular maintenance is key to ensuring that machine guarding fence panels serve their intended purpose. This includes routine inspections for wear and tear, checking for corrosion, and ensuring that panels remain securely fastened. Additionally, any modifications or repairs should be carried out promptly to avoid compromising safety.

It's also beneficial to involve employees in the maintenance process. Training workers to recognize potential issues can lead to quicker resolutions and a more safety-conscious work environment.

Cost Implications of Machine Guarding Fence Panels

Investing in machine guarding fence panels involves upfront costs, but the long-term benefits significantly outweigh these initial expenses. When evaluating cost implications, organizations should consider several factors:

1. **Reduced Injury Costs**: Fewer workplace accidents lead to lower medical expenses and reduced workers' compensation claims.

2. **Compliance Savings**: Avoiding fines associated with non-compliance with safety regulations can save substantial costs.

3. **Increased Productivity**: A safer work environment contributes to higher employee morale and productivity, ultimately benefiting the organization’s bottom line.

Investing in high-quality machine guarding solutions is a proactive approach that pays dividends in terms of safety, compliance, and operational efficiency.

Real-World Case Studies on Machine Guarding Effectiveness

To illustrate the effectiveness of machine guarding fence panels, consider the following case studies:

1. **Manufacturing Facility**: A large manufacturing facility implemented fixed machine guarding solutions around its heavy machinery. Within the first year, the organization reported a 40% decrease in workplace injuries, leading to significant savings in medical and insurance costs.

2. **Construction Site**: A construction company adopted removable machine guarding panels for various equipment. By training employees on their proper use, the company successfully minimized unauthorized access and streamlined maintenance processes, resulting in enhanced safety and efficiency.

These real-world examples underscore the tangible benefits of investing in machine guarding fence panels and highlight their importance in maintaining a secure working environment.

Conclusion: The Future of Machine Guarding in Industrial Settings

As industries continue to evolve and machinery becomes more advanced, the importance of machine guarding fence panels will only grow. Investing in effective guarding solutions not only protects workers but also fosters a culture of safety, compliance, and productivity within the workplace. Companies that prioritize machine guarding will undoubtedly benefit from reduced injuries, lower costs, and a more efficient operational environment.

In summary, the strategic implementation of machine guarding fence panels is not just a regulatory obligation; it is a crucial investment in the safety and well-being of employees, ultimately contributing to long-term success in any industrial setting.

Frequently Asked Questions

1. What are machine guarding fence panels?

Machine guarding fence panels are physical barriers designed to protect workers from hazardous machinery in industrial environments. They help prevent unauthorized access to dangerous areas.

2. Why is machine guarding important?

Machine guarding is essential for enhancing workplace safety, ensuring compliance with regulatory standards, and preventing injuries related to machinery operation.

3. What are the different types of machine guarding solutions?

There are two main types of machine guarding solutions: fixed machine guarding, which provides permanent barriers, and removable machine guarding, which offers flexibility for maintenance and operation.

4. How often should machine guarding panels be inspected?

It's recommended to conduct routine inspections of machine guarding panels at least once a month or after any significant operational changes. Regular maintenance checks ensure that guards remain functional and intact.

5. Can machine guarding panels be customized?

Yes, many manufacturers offer customized machine guarding solutions tailored to specific industrial needs, ensuring compliance with safety regulations while accommodating unique operational requirements.

Hot Products