Top Features to Look for in Quality Machine Guarding Fence Panels

Release Time:

Jul 29,2025

Top Features to Look for in Quality Machine Guarding Fence Panels Introduction to Machine Guarding Fence Panels In today's industrial landscape, **safety** is paramount. As companies strive to maintain productivity while ensuring employee well-being, the importance of high-quality **machine guarding fence panels** cannot be overstated. These panels serve as a crucial barrier between workers and po

Top Features to Look for in Quality Machine Guarding Fence Panels

Introduction to Machine Guarding Fence Panels

In today's industrial landscape, **safety** is paramount. As companies strive to maintain productivity while ensuring employee well-being, the importance of high-quality **machine guarding fence panels** cannot be overstated. These panels serve as a crucial barrier between workers and potentially hazardous machinery, protecting against accidents and injuries. In this article, we will explore the **top features** to consider when selecting machine guarding fence panels, making it easier for businesses to make an informed decision.

Understanding the Importance of Quality Machine Guarding Fence Panels

Machine guarding fence panels are designed to provide a secure perimeter around dangerous machinery. They not only protect workers but also help businesses comply with safety regulations. High-quality panels are essential for reducing the risk of accidents and ensuring a safe working environment. **Investing in the right type of panels can significantly enhance safety standards** and contribute to overall operational efficiency.

Key Features to Look For

When assessing machine guarding fence panels, several key features can help determine their quality and suitability for your specific needs. Below, we will detail these features to aid in your decision-making process.

1. Material Quality and Durability

The material used in machine guarding fence panels is critical. High-quality panels are often made from **steel, aluminum, or reinforced plastic**, each offering unique benefits:

- **Steel Panels**: Known for their strength and durability, steel panels resist bending and breaking under pressure. They are ideal for environments with heavy machinery.

- **Aluminum Panels**: Lightweight yet strong, aluminum is resistant to corrosion, making it suitable for outdoor applications.

- **Reinforced Plastic Panels**: While not as strong as metal, high-grade plastics can provide a balance of affordability and longevity for specific applications.

**Choosing the right material** is essential for long-term performance and safety.

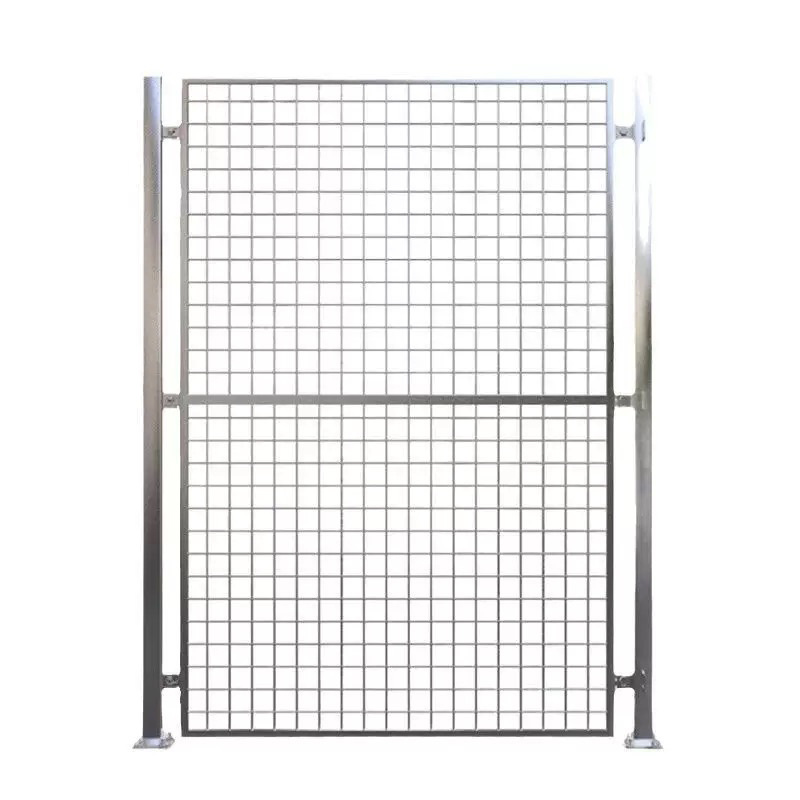

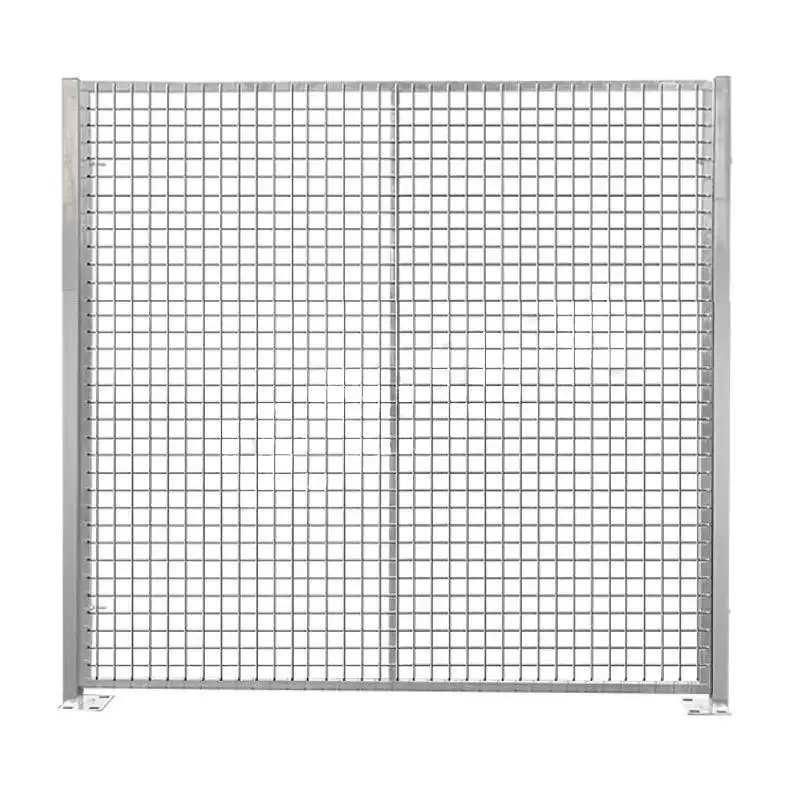

2. Design and Construction

The design of machine guarding fence panels impacts their effectiveness. Features to consider include:

- **Height and Width**: Ensure that the panels are tall enough to prevent accidental contact with machinery. Width should be sufficient to create a secure barrier.

- **Modular Design**: Modular panels offer flexibility, allowing for easy adjustments to the layout as needed. This design can be particularly beneficial in dynamic work environments.

- **Visibility**: Panels should incorporate transparent sections or mesh designs to allow visibility while maintaining safety. This feature enables supervision without compromising protection.

A well-thought-out design enhances both safety and functionality.

3. Safety Features and Compliance

Quality machine guarding fence panels must meet specific safety standards and regulations. Look for:

- **Compliance with OSHA and ANSI Standards**: Ensure that the panels adhere to relevant safety guidelines to avoid legal complications and enhance worker safety.

- **Emergency Access Points**: Panels should include strategically placed access points for emergencies, allowing quick exits when needed.

- **Anti-Tampering Features**: Security measures, such as locks and tamper-proof designs, can prevent unauthorized access to hazardous areas.

Ensuring compliance with safety standards is crucial for maintaining a safe workplace.

4. Installation and Maintenance

Installation and maintenance are practical aspects that can significantly impact your investment. Consider the following:

- **Ease of Installation**: Panels that are easy to install can save time and labor costs. Look for options that include clear assembly instructions and necessary hardware.

- **Low Maintenance Requirements**: Durable materials and designs that resist wear and tear will require less frequent maintenance, allowing for greater focus on core business operations.

Choosing panels that simplify installation and maintenance can lead to substantial long-term savings.

5. Customization Options

Every facility is unique, and having the ability to customize machine guarding fence panels can enhance their effectiveness. Consider:

- **Tailored Sizes and Configurations**: Custom sizes can help fit specific machinery and layouts, ensuring maximum safety.

- **Color and Branding**: Custom colors or branding options can enhance visibility and allow for better integration with your facility's aesthetic.

Customization allows for a more tailored approach to safety.

6. Cost-Effectiveness

While quality is essential, cost is also a significant consideration. Assess the following:

- **Initial Investment vs. Long-Term Savings**: Higher quality panels may require a more substantial upfront investment but can lead to lower long-term costs due to durability and reduced maintenance.

- **Warranty and Support**: Quality manufacturers often provide warranties or support services, adding value to your investment.

A balance between cost and quality is crucial for sustainable investment.

Conclusion

Investing in quality machine guarding fence panels is an essential aspect of maintaining safety and efficiency in industrial settings. By focusing on critical features such as material quality, design, safety compliance, ease of installation, customization options, and cost-effectiveness, businesses can ensure they select the best possible solutions for their unique needs. Remember, prioritizing safety through superior guarding solutions not only protects employees but also enhances overall operational productivity.

Frequently Asked Questions (FAQs)

1. What materials are best for machine guarding fence panels?

The best materials for machine guarding fence panels are typically steel, aluminum, and reinforced plastics. Steel offers strength and durability, aluminum is lightweight and corrosion-resistant, while reinforced plastic provides an affordable option for specific applications.

2. How do I know if the panels comply with safety standards?

To verify compliance, look for panels that meet OSHA and ANSI standards, and check for any certifications or documentation provided by the manufacturer.

3. Can machine guarding fence panels be customized?

Yes, many manufacturers offer customization options, allowing you to tailor sizes, configurations, and colors to fit your specific needs.

4. What is the average lifespan of machine guarding fence panels?

The lifespan of machine guarding fence panels varies based on materials and usage, but high-quality steel panels can last several years with proper maintenance.

5. How much do machine guarding fence panels cost?

Prices for machine guarding fence panels vary widely based on materials, size, and customization options. It’s essential to balance initial costs with long-term durability and maintenance expenses when making a decision.

Hot Products