Ensuring Workplace Safety: The Importance of Fencing Machine Guarding

Release Time:

Jul 31,2025

--- In the realm of workplace safety, the implementation of effective safety fencing and machine guarding is paramount. This safety measure serves as a crucial line of defense against potential hazards associated with machinery operations. The primary objective of safety fencing is to create a physical barrier that restricts unauthorized access to dangerous areas, thus reducing the risk of acciden

---

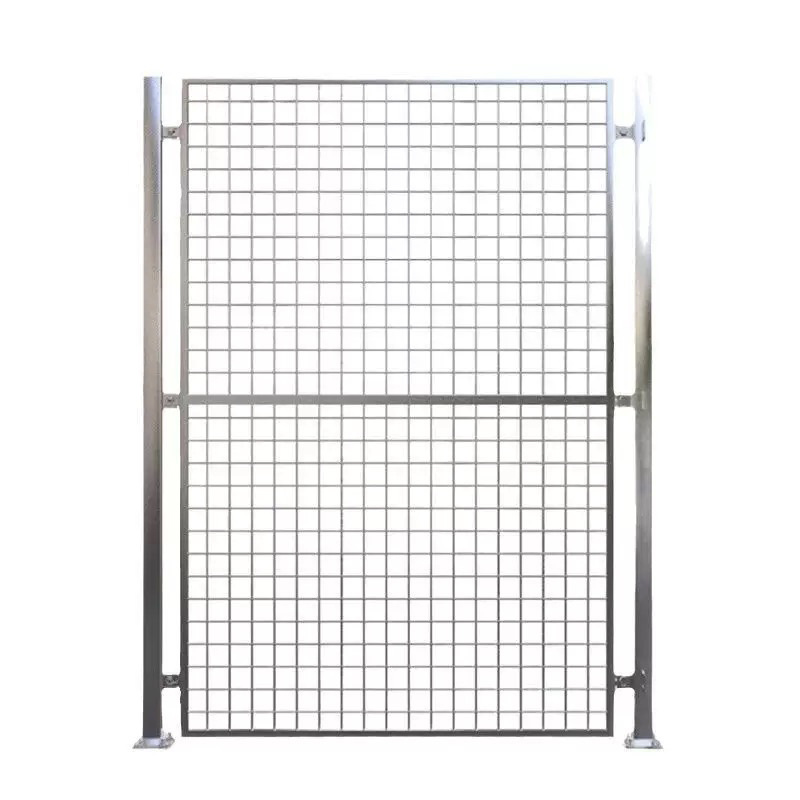

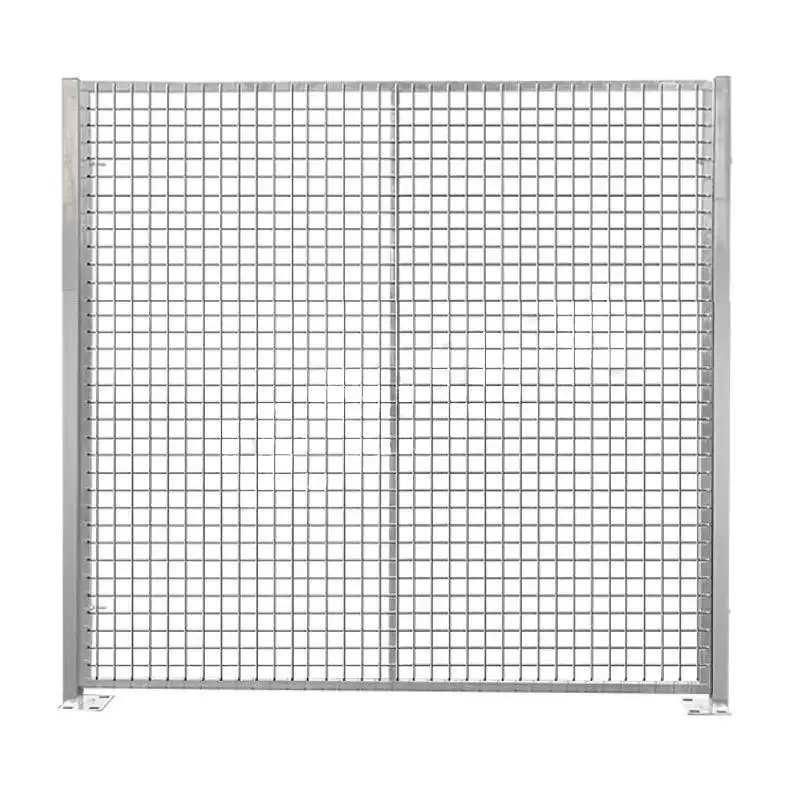

In the realm of workplace safety, the implementation of effective safety fencing and machine guarding is paramount. This safety measure serves as a crucial line of defense against potential hazards associated with machinery operations. The primary objective of safety fencing is to create a physical barrier that restricts unauthorized access to dangerous areas, thus reducing the risk of accidents and injuries.

Safety fencing is designed to withstand various impacts and environmental conditions, making it an ideal choice for industrial settings. It not only protects workers but also ensures compliance with safety regulations. This is particularly important in workplaces where heavy machinery is used, as the risk of injury can significantly increase without proper guarding in place.

One of the key benefits of safety fencing is its ability to delineate hazardous zones clearly. By visually signifying restricted areas, workers can easily recognize where to exercise caution. This visual cue is essential in preventing accidents, especially in environments where multiple tasks are performed simultaneously. Furthermore, safety fencing can be customized to fit specific machinery or operational needs, ensuring that all potential hazards are adequately addressed.

Additionally, machine guarding plays an indispensable role in maintaining a safe operational environment. Guards are engineered to protect workers from moving parts, sharp edges, and other potential dangers. These guards can be fixed, adjustable, or self-adjusting, depending on the machinery's requirements. Proper machine guarding not only prevents injuries but also enhances the longevity of the equipment by minimizing wear and tear caused by human interaction.

Moreover, regular inspections and maintenance of safety fencing and machine guards are essential for ensuring their effectiveness. Employers should establish a routine check system to identify any wear or damage that may compromise the integrity of these safety features. This proactive approach not only protects employees but also helps in minimizing downtime caused by accidents.

Training employees on the importance of adhering to safety fencing guidelines and machine guarding protocols is equally vital. Workers should be educated about the risks associated with machine operations and the significance of staying within designated safe zones. Creating a culture of safety within the workplace leads to increased awareness and responsibility among staff.

In conclusion, safety fencing and machine guarding are critical components of a comprehensive workplace safety strategy. By investing in these protective measures, employers can foster a safer work environment, ultimately leading to improved productivity and a reduction in workplace accidents. Prioritizing safety not only protects workers but also enhances the overall operational efficiency of an organization, making it a win-win situation for everyone involved.

In the realm of workplace safety, the implementation of effective safety fencing and machine guarding is paramount. This safety measure serves as a crucial line of defense against potential hazards associated with machinery operations. The primary objective of safety fencing is to create a physical barrier that restricts unauthorized access to dangerous areas, thus reducing the risk of accidents and injuries.

Safety fencing is designed to withstand various impacts and environmental conditions, making it an ideal choice for industrial settings. It not only protects workers but also ensures compliance with safety regulations. This is particularly important in workplaces where heavy machinery is used, as the risk of injury can significantly increase without proper guarding in place.

One of the key benefits of safety fencing is its ability to delineate hazardous zones clearly. By visually signifying restricted areas, workers can easily recognize where to exercise caution. This visual cue is essential in preventing accidents, especially in environments where multiple tasks are performed simultaneously. Furthermore, safety fencing can be customized to fit specific machinery or operational needs, ensuring that all potential hazards are adequately addressed.

Additionally, machine guarding plays an indispensable role in maintaining a safe operational environment. Guards are engineered to protect workers from moving parts, sharp edges, and other potential dangers. These guards can be fixed, adjustable, or self-adjusting, depending on the machinery's requirements. Proper machine guarding not only prevents injuries but also enhances the longevity of the equipment by minimizing wear and tear caused by human interaction.

Moreover, regular inspections and maintenance of safety fencing and machine guards are essential for ensuring their effectiveness. Employers should establish a routine check system to identify any wear or damage that may compromise the integrity of these safety features. This proactive approach not only protects employees but also helps in minimizing downtime caused by accidents.

Training employees on the importance of adhering to safety fencing guidelines and machine guarding protocols is equally vital. Workers should be educated about the risks associated with machine operations and the significance of staying within designated safe zones. Creating a culture of safety within the workplace leads to increased awareness and responsibility among staff.

In conclusion, safety fencing and machine guarding are critical components of a comprehensive workplace safety strategy. By investing in these protective measures, employers can foster a safer work environment, ultimately leading to improved productivity and a reduction in workplace accidents. Prioritizing safety not only protects workers but also enhances the overall operational efficiency of an organization, making it a win-win situation for everyone involved.

Hot Products