Why Your Business Needs Efficient Machine Guarding Fence Panels

Release Time:

Aug 06,2025

Why Your Business Needs Efficient Machine Guarding Fence Panels In today's fast-paced industrial environment, safety is paramount. As businesses strive to improve efficiency and productivity, the need for **effective safety measures** cannot be overstated. One of the most crucial components in ensuring workplace safety is the implementation of **efficient machine guarding fence panels**. These spe

Why Your Business Needs Efficient Machine Guarding Fence Panels

In today's fast-paced industrial environment, safety is paramount. As businesses strive to improve efficiency and productivity, the need for **effective safety measures** cannot be overstated. One of the most crucial components in ensuring workplace safety is the implementation of **efficient machine guarding fence panels**. These specialized fences not only protect employees from hazardous machinery but also enhance operational efficiency. In this article, we will explore the importance of machine guarding fence panels, their benefits, and how to choose the right solutions for your business.

Understanding Machine Guarding Fence Panels

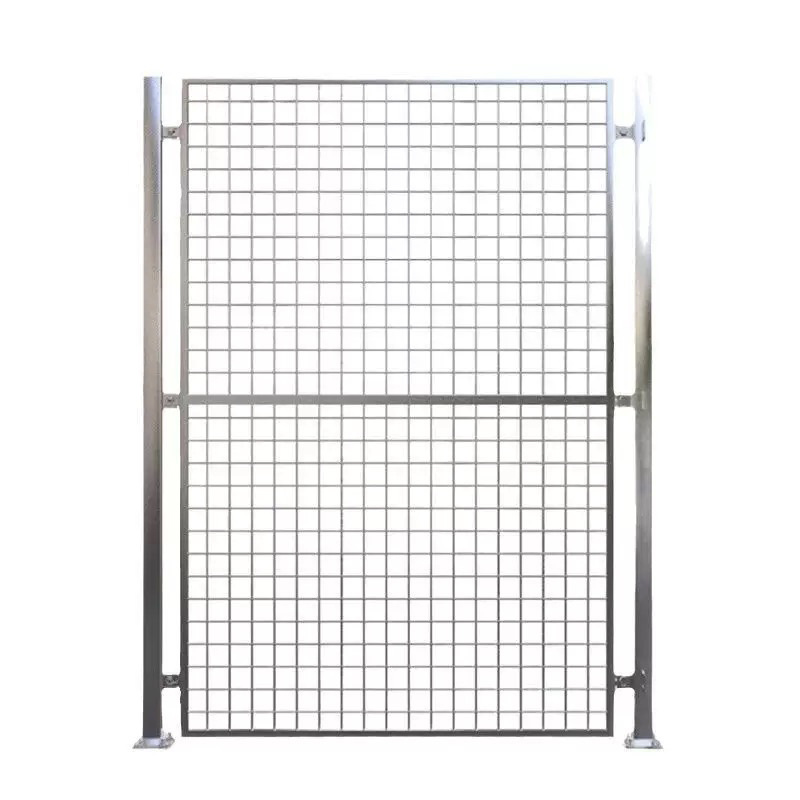

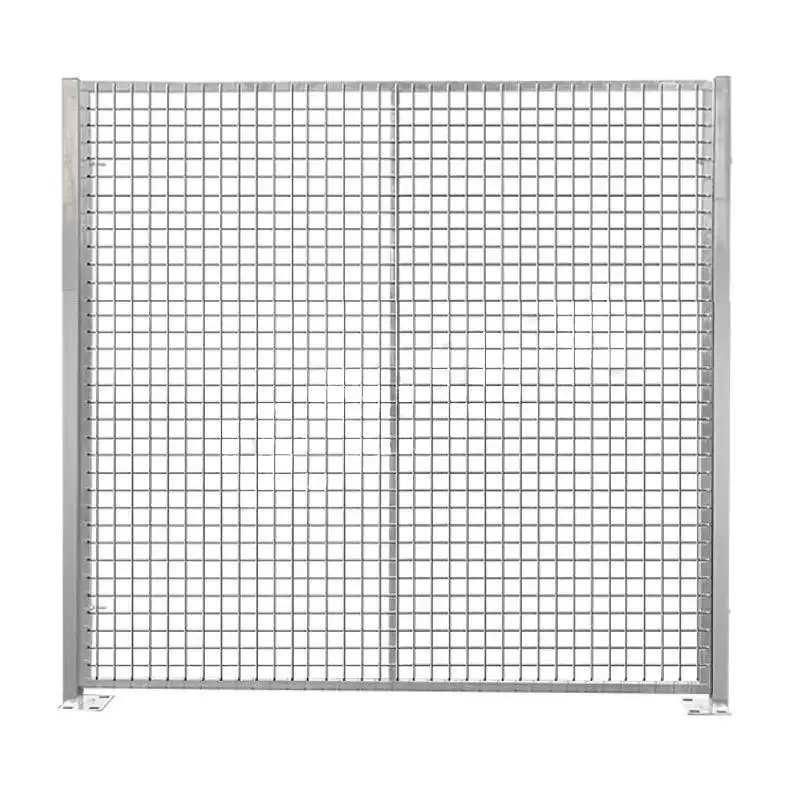

Machine guarding fence panels are designed to create a physical barrier between workers and dangerous machinery. They are typically made from durable materials like steel or heavy-duty plastic and are built to withstand impacts, ensuring long-term use. But why do businesses need these panels?

1. Enhancing Workplace Safety

Workplace safety is a critical concern for any organization. Machine guarding fence panels serve as a proactive measure to prevent accidents and injuries associated with heavy machinery. By creating a designated safety perimeter, these panels ensure that employees and visitors are kept at a safe distance from potentially hazardous equipment.

The Importance of Safety Compliance

In many industries, compliance with safety regulations is not just a precaution but a legal requirement. Machine guarding fence panels help businesses meet these requirements, reducing the risk of fines and legal repercussions. **Investing in safety** can also enhance a company's reputation, demonstrating a commitment to the well-being of its workforce.

2. Increasing Operational Efficiency

While the primary purpose of machine guarding fence panels is safety, they also play a crucial role in enhancing operational efficiency. By clearly defining boundaries around machinery, these panels help streamline workflows. Employees can focus on their tasks without the distraction of potential hazards, and machinery can operate at its full capacity without unnecessary interruptions.

Reducing Downtime

Accidents can lead to significant downtime, impacting productivity and financial performance. By implementing efficient machine guarding fence panels, businesses can minimize the risk of accidents. This, in turn, helps maintain a smooth production flow and reduces operational costs associated with workplace incidents.

3. Customization Options for Your Business Needs

Every business is unique, and so are its safety requirements. Machine guarding fence panels are highly customizable to fit specific operational needs. Whether you require permanent installations or adjustable solutions for fluctuating workloads, there are options available to suit your environment.

Choosing the Right Material

When selecting machine guarding fence panels, the choice of material is crucial. Steel panels offer high durability and resistance to impact, while plastic options can be more lightweight and flexible. Evaluating the specific hazards present in your workplace will guide you in choosing the most suitable material for your fencing solution.

4. Cost-Effectiveness of Efficient Fencing Solutions

Investing in machine guarding fence panels can be viewed as a significant upfront cost; however, the long-term benefits outweigh the initial investment. The financial implications of workplace accidents, including medical expenses, legal fees, and lost productivity, can far exceed the cost of implementing effective safety measures.

Long-Term Savings through Safety Investment

By ensuring a safer working environment, businesses can reduce insurance premiums and decrease the likelihood of costly lawsuits. Moreover, maintaining a healthy workforce leads to improved morale and productivity, further enhancing overall profitability.

Key Features to Look for in Machine Guarding Fence Panels

To ensure that your investment in machine guarding fence panels is worthwhile, it’s essential to consider specific features that enhance safety and functionality.

1. Durability and Strength

The effectiveness of a machine guarding fence panel relies significantly on its durability. Look for panels constructed from high-grade materials that can withstand wear and tear, impacts, and harsh environmental conditions.

2. Visibility and Design

A well-designed fence panel should offer visibility while maintaining a secure barrier. Mesh designs provide visibility into the work area, allowing for better monitoring of machinery and personnel while ensuring safety.

3. Ease of Installation and Maintenance

Choose fence panels that are easy to install and require minimal maintenance. This not only saves time during setup but also reduces downtime for regular upkeep. Modular designs can be advantageous, allowing for quick adjustments as needed.

4. Compliance with Safety Standards

Ensure that the machine guarding fence panels comply with relevant safety regulations and standards. This compliance will not only enhance safety but also protect your business from potential liabilities.

The Installation Process of Machine Guarding Fence Panels

Installing machine guarding fence panels is a straightforward process, but it requires careful planning and execution to ensure optimal safety and efficiency.

1. Assessing the Work Environment

Before installation, it is crucial to assess the workspace. Identify the areas that require guarding and evaluate existing hazards. Conducting a thorough risk assessment will guide your decisions regarding the placement and specifications of the fence panels.

2. Designing the Fence Layout

Once the assessment is complete, design the layout for your fence. Consider the flow of work and ensure that the barrier does not obstruct operations. Properly planned layouts will help maintain productivity while ensuring safety.

3. Installing the Panels

Follow the manufacturer’s guidelines during installation to ensure the panels are securely mounted. It is advisable to have a professional team handle the installation, particularly for larger or more complex environments.

Maintaining Your Machine Guarding Fence Panels

Regular maintenance of machine guarding fence panels is essential to ensure their effectiveness over time. Here are some key maintenance practices:

1. Routine Inspections

Schedule regular inspections to identify any damage or wear that could compromise safety. Look for signs of rust, loose fittings, or structural weaknesses.

2. Cleaning and Upkeep

Keep the panels clean to maintain visibility and functionality. Regular cleaning also helps prevent corrosion and prolongs the life of the panels.

3. Immediate Repairs

Address any damages immediately to prevent accidents. Prompt repairs will also help maintain compliance with safety standards.

FAQs About Machine Guarding Fence Panels

1. What industries benefit from machine guarding fence panels?

Machine guarding fence panels are beneficial across various industries, including manufacturing, construction, logistics, and any sector involving heavy machinery or hazardous equipment.

2. Are machine guarding fence panels customizable?

Yes, many manufacturers offer customizable options to fit specific business needs, including size, material, and design.

3. How do machine guarding fence panels improve compliance?

By implementing effective machine guarding fence panels, businesses can meet safety regulations set by governing bodies, reducing the risk of fines and legal issues.

4. What materials are commonly used for machine guarding fence panels?

Typically, machine guarding fence panels are made from steel or heavy-duty plastic, chosen for their durability and strength.

5. How often should machine guarding fence panels be inspected?

Regular inspections should be conducted at least quarterly or after any significant incidents to ensure the panels remain effective and safe.

Conclusion

Investing in **efficient machine guarding fence panels** is not merely a regulatory requirement; it is a strategic decision that enhances workplace safety, boosts operational efficiency, and protects your workforce and assets. By understanding the importance of these panels and choosing the right solutions tailored to your business needs, you can create a safer working environment that fosters productivity and compliance. Ultimately, the long-term benefits of implementing effective machine guarding solutions far outweigh the initial investment, making it a wise choice for any business committed to excellence and safety.

Hot Products