Ensuring Safety with Frameless Bending Robot Safety Fences in the Consumer Electronics Industry

Release Time:

Aug 07,2025

In the ever-evolving landscape of consumer electronics, safety is paramount, particularly when integrating automation technologies like bending robots. The adoption of frameless bending robot safety fences has become increasingly significant in ensuring a secure working environment. These safety fences are designed to provide an unobtrusive yet effective barrier around automated machinery, safegua

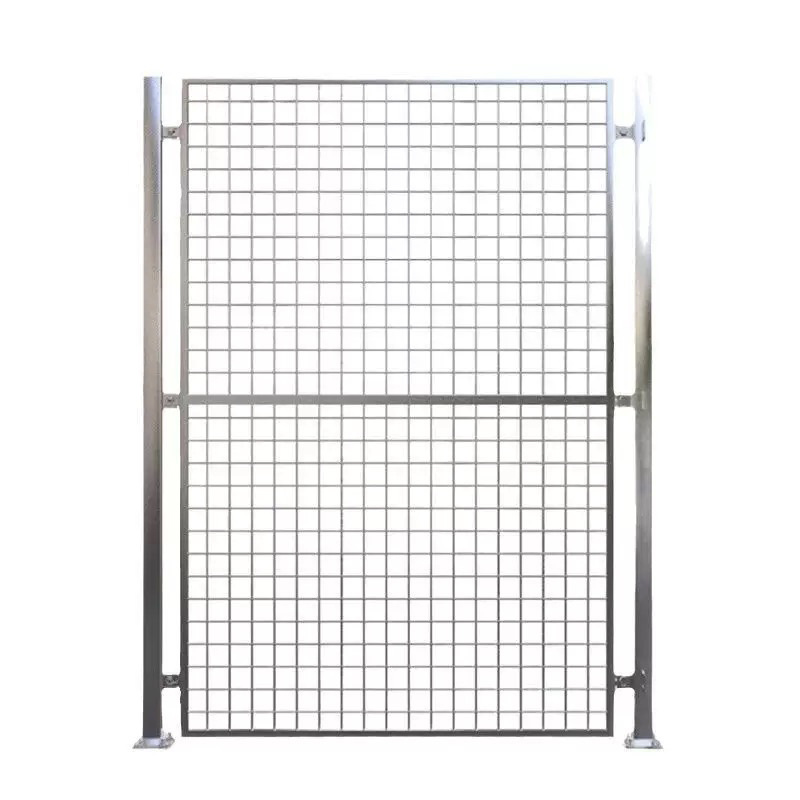

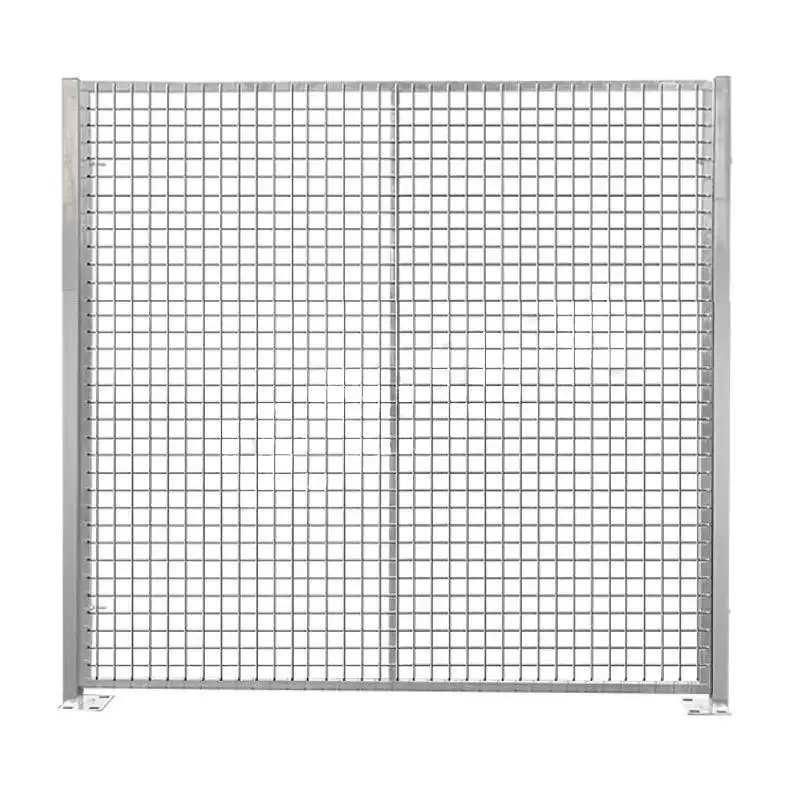

In the ever-evolving landscape of consumer electronics, safety is paramount, particularly when integrating automation technologies like bending robots. The adoption of frameless bending robot safety fences has become increasingly significant in ensuring a secure working environment. These safety fences are designed to provide an unobtrusive yet effective barrier around automated machinery, safeguarding personnel while maintaining workflow efficiency.

One of the primary advantages of frameless bending robot safety fences is their minimalist design. Unlike traditional safety barriers, which can obstruct visibility and impede access, frameless fences are designed to be transparent and versatile. This feature allows for unobstructed views of the workspace, enabling operators to monitor processes without physical barriers. Moreover, the lightweight materials used in frameless fences contribute to easier installation and reconfiguration, making them a practical option for dynamic production environments.

Additionally, the implementation of frameless bending robot safety fences plays a crucial role in compliance with safety regulations. Regulatory bodies often outline stringent guidelines concerning workplace safety, especially in industries involving automated machinery. By utilizing these fences, companies can demonstrate their commitment to adhering to safety standards, thereby minimizing the risk of workplace accidents and enhancing overall employee wellbeing.

From a functional standpoint, frameless bending robot safety fences are designed to integrate seamlessly with existing automation systems. Many models feature modular designs that facilitate quick assembly and disassembly. This adaptability is particularly beneficial in fast-paced sectors like finance and commercial electronics, where operational layouts may frequently change due to new projects or equipment upgrades. Enhanced flexibility allows businesses to respond promptly to market demands while maintaining strict safety protocols.

Moreover, the installation of frameless safety fences can lead to operational efficiency. By clearly defining safe zones around bending robots, these fences help streamline workflows and reduce the likelihood of human error. Employees can navigate the workspace more confidently, knowing that they are protected from potential hazards during interactions with automated systems.

In conclusion, the use of frameless bending robot safety fences is an essential investment for businesses in the consumer electronics sector. Their aesthetic appeal, regulatory compliance, and enhancement of operational efficiency make them an invaluable asset in maintaining a safe and productive work environment. As automation continues to shape the future of industry, prioritizing safety through innovative solutions like frameless safety fences will become increasingly critical for successful operations.

One of the primary advantages of frameless bending robot safety fences is their minimalist design. Unlike traditional safety barriers, which can obstruct visibility and impede access, frameless fences are designed to be transparent and versatile. This feature allows for unobstructed views of the workspace, enabling operators to monitor processes without physical barriers. Moreover, the lightweight materials used in frameless fences contribute to easier installation and reconfiguration, making them a practical option for dynamic production environments.

Additionally, the implementation of frameless bending robot safety fences plays a crucial role in compliance with safety regulations. Regulatory bodies often outline stringent guidelines concerning workplace safety, especially in industries involving automated machinery. By utilizing these fences, companies can demonstrate their commitment to adhering to safety standards, thereby minimizing the risk of workplace accidents and enhancing overall employee wellbeing.

From a functional standpoint, frameless bending robot safety fences are designed to integrate seamlessly with existing automation systems. Many models feature modular designs that facilitate quick assembly and disassembly. This adaptability is particularly beneficial in fast-paced sectors like finance and commercial electronics, where operational layouts may frequently change due to new projects or equipment upgrades. Enhanced flexibility allows businesses to respond promptly to market demands while maintaining strict safety protocols.

Moreover, the installation of frameless safety fences can lead to operational efficiency. By clearly defining safe zones around bending robots, these fences help streamline workflows and reduce the likelihood of human error. Employees can navigate the workspace more confidently, knowing that they are protected from potential hazards during interactions with automated systems.

In conclusion, the use of frameless bending robot safety fences is an essential investment for businesses in the consumer electronics sector. Their aesthetic appeal, regulatory compliance, and enhancement of operational efficiency make them an invaluable asset in maintaining a safe and productive work environment. As automation continues to shape the future of industry, prioritizing safety through innovative solutions like frameless safety fences will become increasingly critical for successful operations.

Hot Products