Why Every Business Needs Industrial Safety Railings for Enhanced Security

Release Time:

Sep 10,2025

Why Every Business Needs Industrial Safety Railings for Enhanced Security Table of Contents 1. Understanding Industrial Safety Railings 2. The Importance of Safety in the Workplace 3. Key Benefits of Industrial Safety Railings 3.1. Enhancing Employee Safety 3.2. Reducing Liability and Insurance Costs 3.3. Ensuring Compliance with Safety Regulations 4. Types of Industrial Safety Rai

Why Every Business Needs Industrial Safety Railings for Enhanced Security

Table of Contents

1. Understanding Industrial Safety Railings

2. The Importance of Safety in the Workplace

3. Key Benefits of Industrial Safety Railings

3.1. Enhancing Employee Safety

3.2. Reducing Liability and Insurance Costs

3.3. Ensuring Compliance with Safety Regulations

4. Types of Industrial Safety Railings

4.1. Fixed Safety Railings

4.2. Movable Safety Railings

4.3. Modular Safety Railings

5. Best Practices for Installing Industrial Safety Railings

6. Common Misconceptions About Safety Railings

7. Frequently Asked Questions (FAQs)

8. Conclusion: Investing in Safety for a Secure Future

1. Understanding Industrial Safety Railings

Industrial safety railings are essential safety features designed to prevent falls and accidents in workplaces. Typically constructed from robust materials such as steel or aluminum, these railings provide a physical barrier that protects employees and equipment in high-risk areas. They can be found in various environments, including factories, warehouses, construction sites, and commercial buildings.

2. The Importance of Safety in the Workplace

Safety in the workplace is paramount for any business. **A safe work environment not only protects employees** but also enhances productivity and promotes job satisfaction. When employees feel secure, they are more focused on their tasks, leading to higher efficiency and reduced turnover rates.

Furthermore, workplace accidents can have devastating consequences, including serious injuries, fatalities, and extensive financial losses. Therefore, investing in safety measures, such as industrial safety railings, is not just an ethical responsibility but a strategic business decision.

3. Key Benefits of Industrial Safety Railings

Understanding the key benefits of industrial safety railings can help business owners appreciate their necessity. Here are three primary advantages.

3.1. Enhancing Employee Safety

The primary function of industrial safety railings is to **enhance employee safety**. These railings prevent falls and provide a secure barrier in areas where the risk of accidents is high, such as staircases, elevated platforms, and near machinery. By installing safety railings, businesses can significantly reduce the chances of workplace injuries, fostering a safer environment for all employees.

3.2. Reducing Liability and Insurance Costs

Another critical advantage of implementing safety railings is the potential to **reduce liability and insurance costs**. In the event of an accident, a business may face legal claims and increased insurance premiums. Safety railings serve as a proactive measure to minimize risks, thus protecting the company from costly lawsuits and financial implications.

Moreover, businesses that prioritize safety often enjoy lower insurance premiums, as insurance providers recognize the reduced risk associated with a safe working environment.

3.3. Ensuring Compliance with Safety Regulations

Compliance with safety regulations is a legal requirement for all businesses. Governments and safety organizations have established standards to ensure workplace safety, and failure to comply can lead to severe penalties. **Industrial safety railings help businesses meet these regulations,** ensuring that they adhere to safety codes and guidelines. By proactively investing in safety measures, businesses can avoid fines and demonstrate their commitment to employee well-being.

4. Types of Industrial Safety Railings

There are several types of industrial safety railings available, each designed for specific applications. Understanding these types can help businesses choose the most suitable option for their needs.

4.1. Fixed Safety Railings

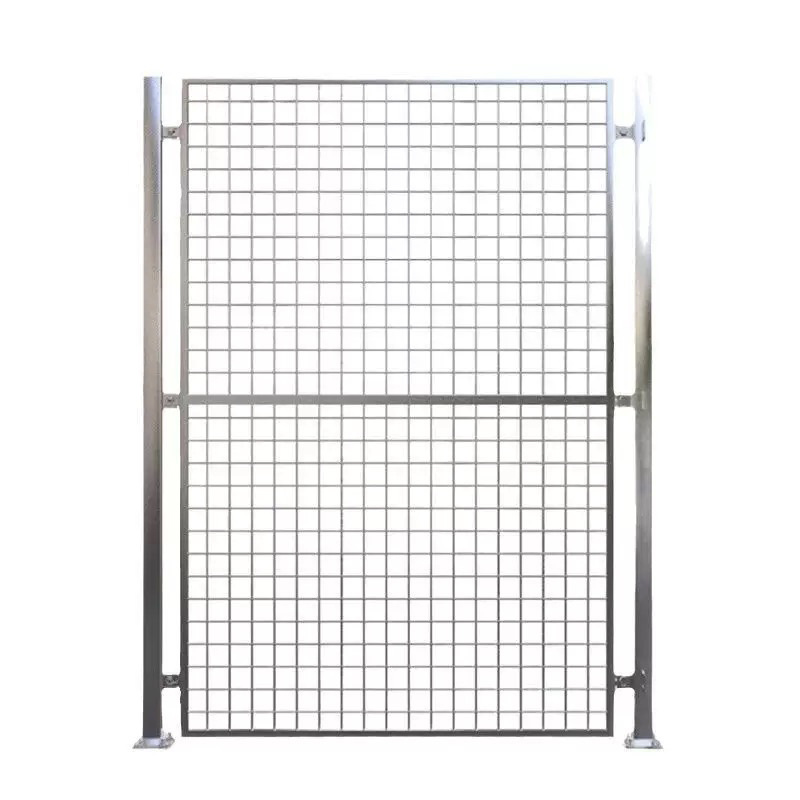

Fixed safety railings are permanently installed in a specific location and provide a robust barrier. These railings are often used in stairwells, elevated platforms, and loading docks, ensuring that employees have a secure point of reference.

4.2. Movable Safety Railings

Movable safety railings offer flexibility, allowing businesses to adjust their positioning as needed. These railings are ideal for environments that require frequent changes in layout, such as warehouses or manufacturing floors.

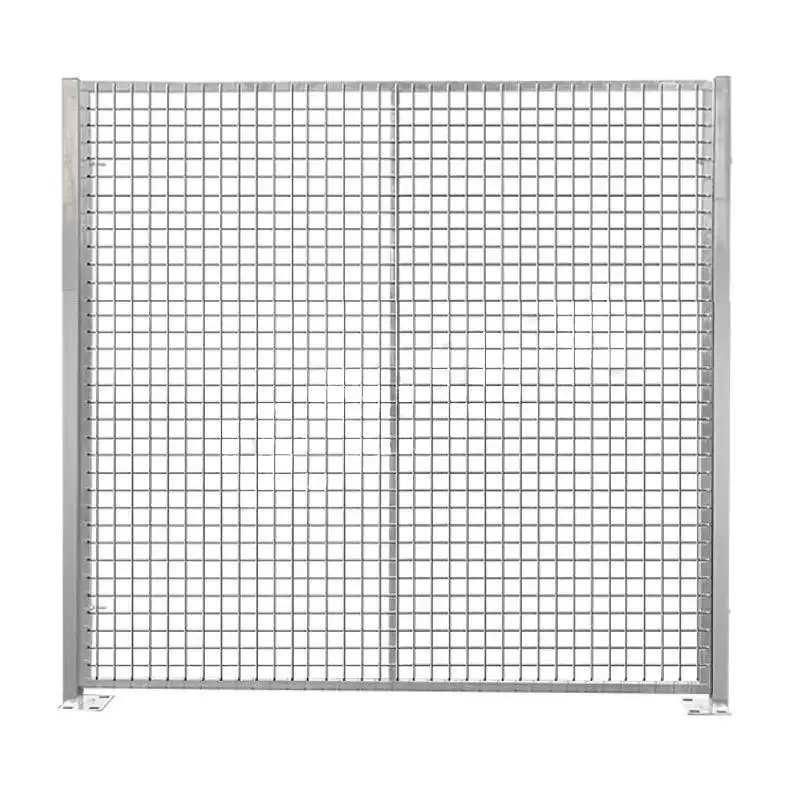

4.3. Modular Safety Railings

Modular safety railings are customizable systems that can be tailored to fit specific work areas. These railings can be easily reconfigured or expanded, providing a versatile solution for businesses with dynamic environments.

5. Best Practices for Installing Industrial Safety Railings

To ensure the effectiveness of industrial safety railings, businesses should follow best practices during installation. Here are some essential tips:

1. **Conduct a Risk Assessment:** Evaluate the workplace to identify high-risk areas that require safety railings.

2. **Choose Quality Materials:** Select durable materials that can withstand environmental factors such as weather and wear.

3. **Engage Professional Installers:** Hire experienced professionals to install safety railings, ensuring they meet safety standards and regulations.

4. **Regular Maintenance:** Perform routine inspections and maintenance to ensure the integrity and safety of the railings over time.

6. Common Misconceptions About Safety Railings

Despite their importance, there are common misconceptions regarding industrial safety railings. Addressing these myths is crucial for business owners:

1. **Myth: Safety Railings Are Optional:** Some businesses view safety railings as optional, but they are crucial for ensuring employee safety and compliance with regulations.

2. **Myth: All Railings Are the Same:** Not all railings are created equal. Businesses must choose railings tailored to their specific needs and industry standards.

3. **Myth: Safety Railings Are Costly:** While there may be initial costs associated with purchasing and installing safety railings, the long-term benefits and potential savings on liability and insurance costs make them a worthwhile investment.

7. Frequently Asked Questions (FAQs)

**Q1: What are the main benefits of installing industrial safety railings?**

A1: The main benefits include enhancing employee safety, reducing liability and insurance costs, and ensuring compliance with safety regulations.

**Q2: How do I determine where to install safety railings?**

A2: Conduct a risk assessment to identify high-risk areas, such as stairwells, elevated platforms, and machinery zones.

**Q3: How often should safety railings be inspected?**

A3: It is recommended to perform routine inspections at least once a year, or more frequently in high-traffic areas.

**Q4: Are there specific regulations for safety railings?**

A4: Yes, regulations vary by location and industry. It is essential to check local safety codes and compliance requirements.

**Q5: Can safety railings be customized?**

A5: Yes, many safety railings are modular and can be customized to fit specific work environments and requirements.

8. Conclusion: Investing in Safety for a Secure Future

In conclusion, the importance of industrial safety railings cannot be overstated. They play a vital role in enhancing security, protecting employees, and ensuring compliance with regulations. By investing in safety railings, businesses not only create a safer work environment but also reduce potential liabilities and insurance costs. With various types available, companies can choose the best solution tailored to their specific needs. Ultimately, prioritizing safety is an investment in the present and future success of any business.

Hot Products